Rapid Machine Shop LLC is able to restore any lost data in the event of a disaster, immediately with multiple restore options.

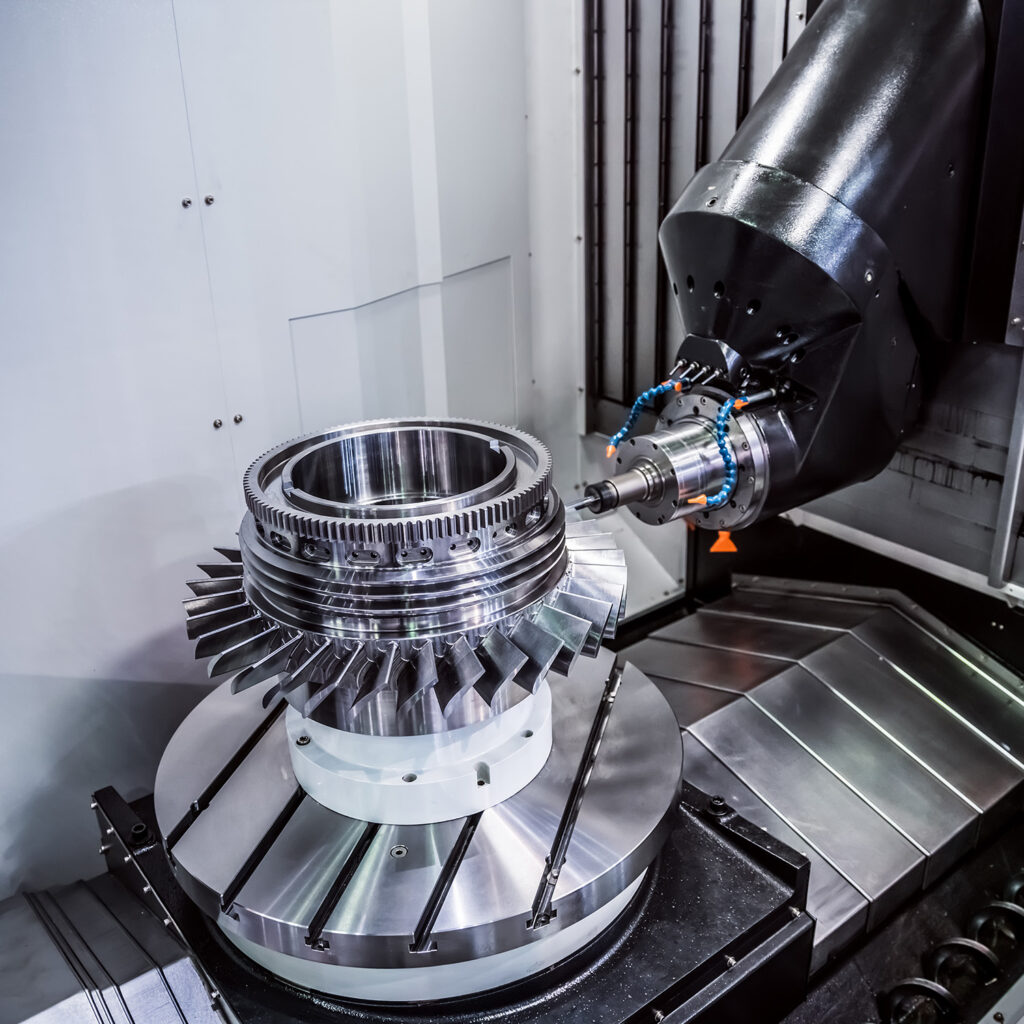

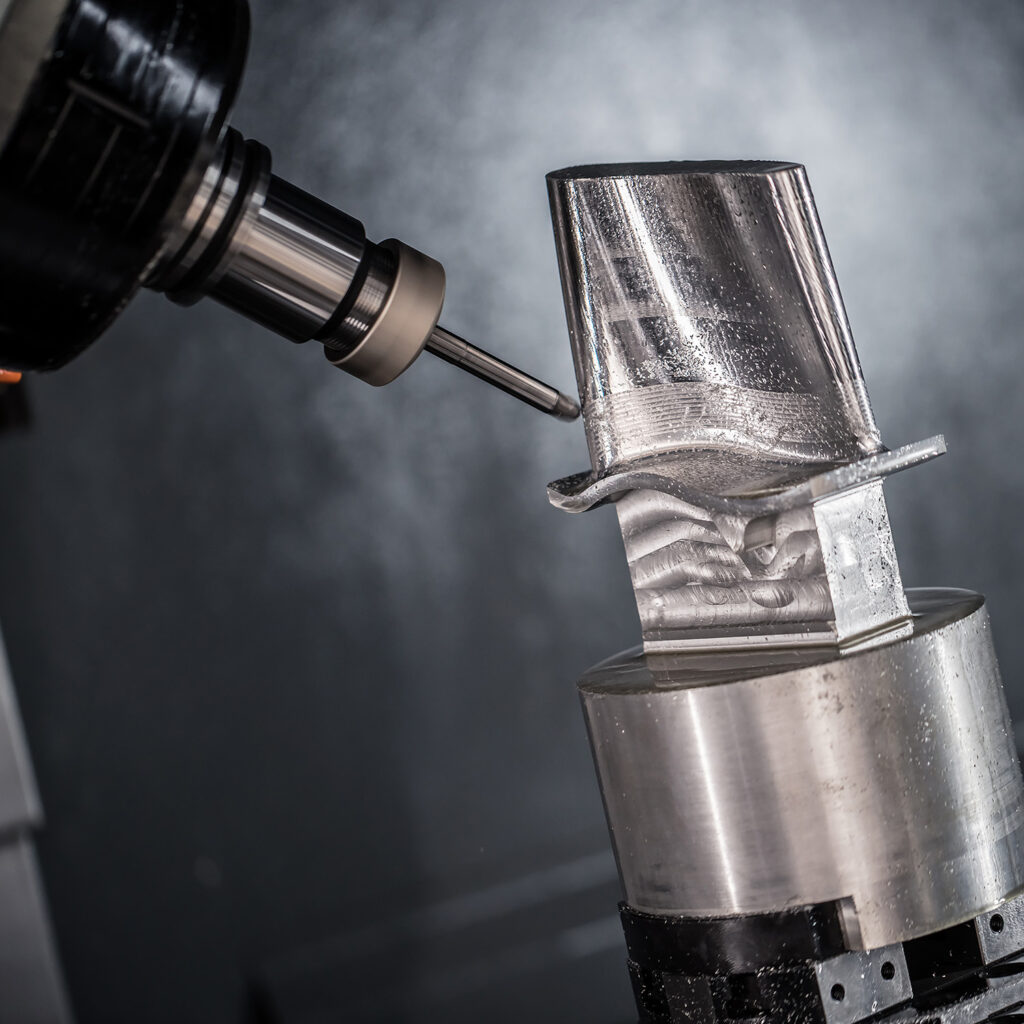

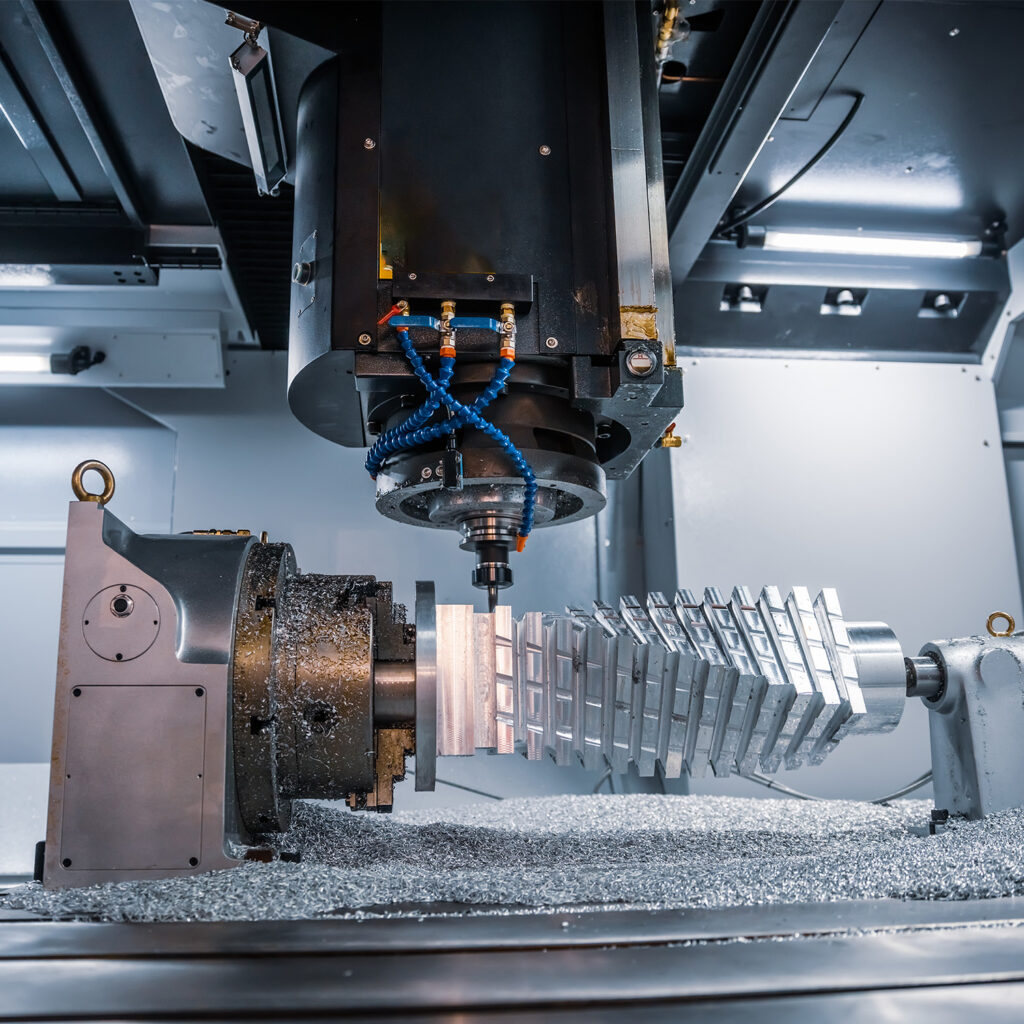

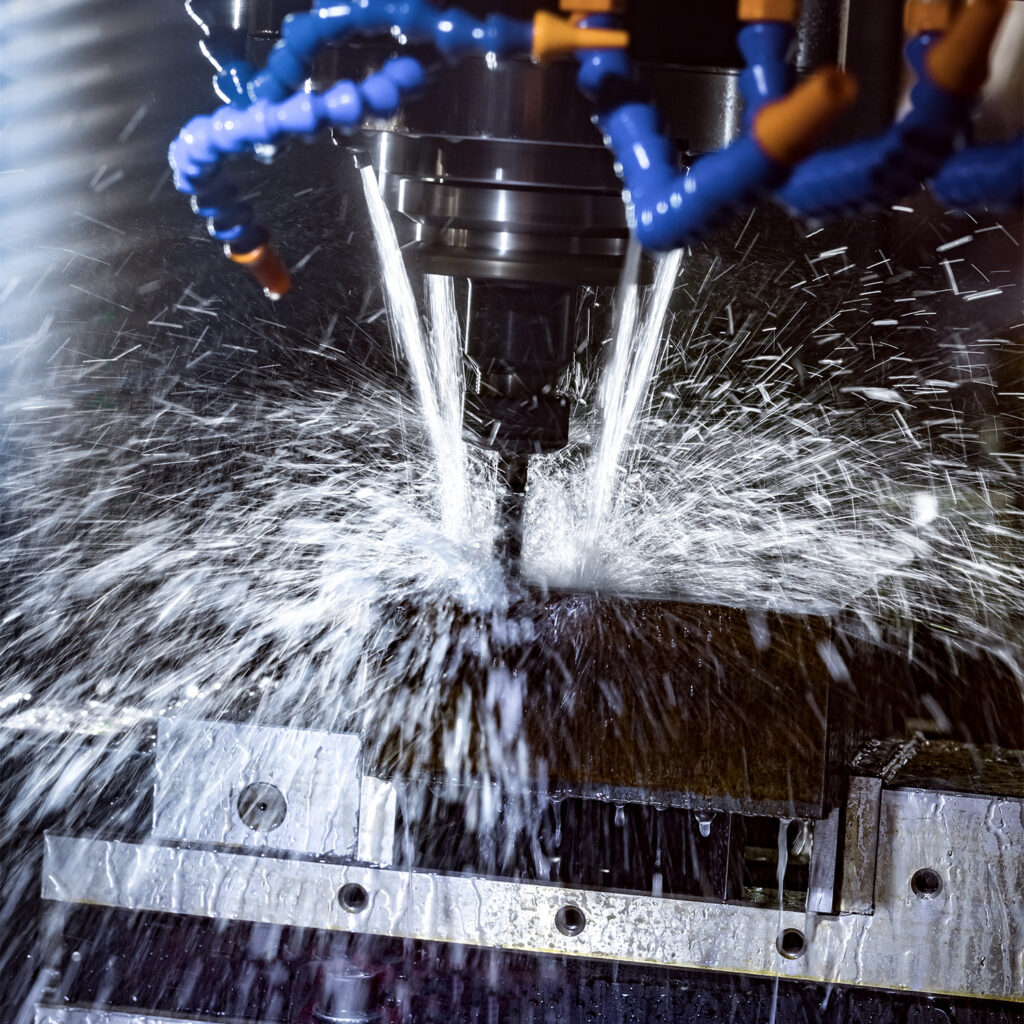

Our shop is equipped with CNC machines, 4th axis to increase productivity, and repeatable volumetric accuracy, our 4th axis machines eliminate the need for secondary operations improving quality and avoiding the possibility of human error.

We have the ability to machine with the precision requirements of our customer’s specifications for accurate part production in closed tolerance and true positioning hard to envision.

Our Company has embraced on-time delivery and quality, and continues to improve our business.

Precision inspection metrology gear has been introduced to suit the accuracy of our customers, using a portable articulating arm on a stationary base. RPS CMM portable articulating Arm 3 dimensional.

(CERTIFIED SKILL-METRIC TECHNICIAN IN HOUSE)

Software and mechanical engineering are key factors for quality products we have personnel with more than 30 years combined experience in manufacturing, quality workmanship, design, programming, and quality control.

All projects run to a particular shop traveler package to transport safe and efficient, and to schedule manufacturing, we check drawings, models, programs, fixtures, materials, and tools necessary to support production. We provide our customers copies of certificate of conformance, material certificates, outside process certifications, and inspection report from our CMM.

At Rapid Machine Shop we can construct CAD models from blueprints Reverse engineering or translate data from CAD to NC files from any number of sources our CNC programmer department uses CAD-CAM Software Master-Cam, direct download from a central computer room to our CNC mills and lathes via a network. (CERTIFIED PROGRAMMER IN HOUSE)